Custom Order Picker Base

December 8, 2021

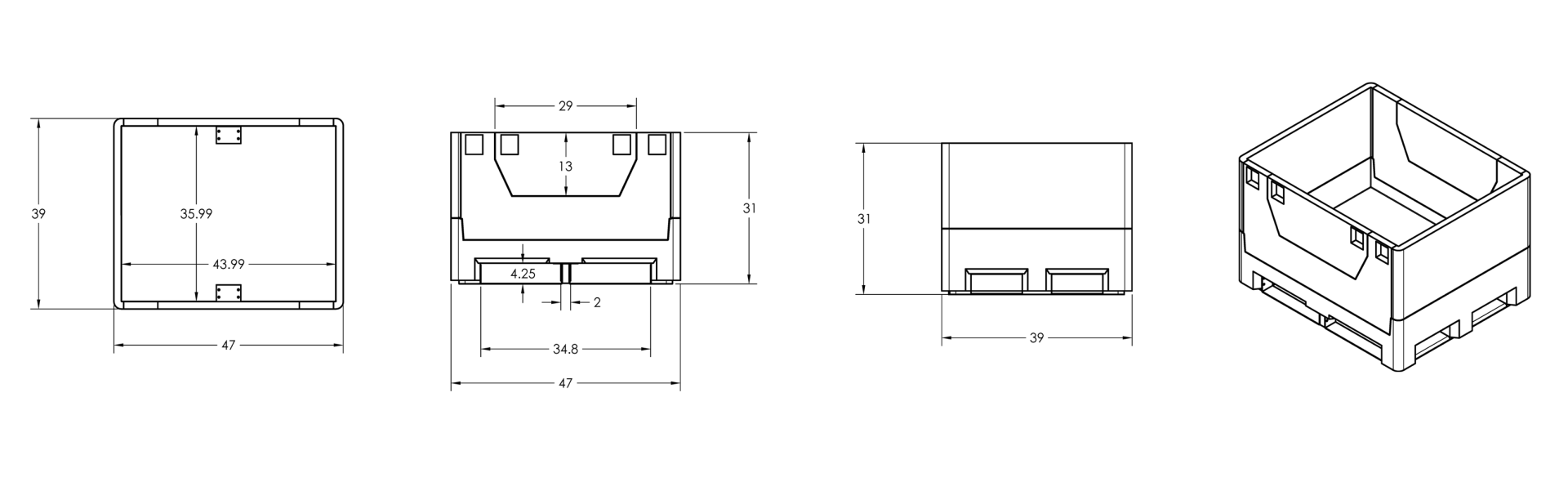

What is an order picker base?

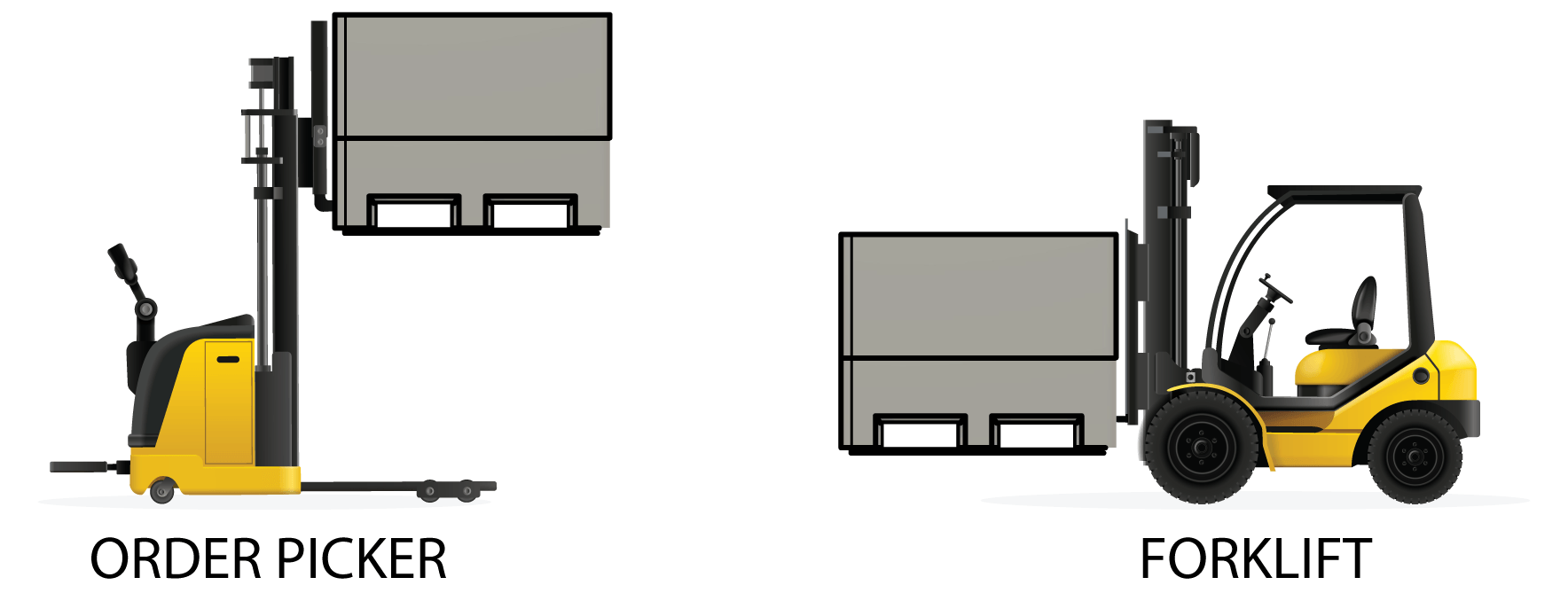

Not all fork trucks are made the same. Your standard forklift is designed to lift your material for storage or retrieve it when needed. This is accomplished by having fork tines on hydraulics that can be raised up or down to fit into a palletized base’s cavities to secure your product. On the other hand, an order picker is designed to take the driver up with them.

Order pickers are used more in a warehouse setting where you might not need a whole container or pallet of items at a time. It would be inefficient to bring a whole bin down just to get one or two small parts out and then restack it. In these cases, the driver can move up with the fork prongs, remove, load, or scan the proper material, and then continue with their job.

Whereas most forklifts can be set to fit the bases of collapsible plastic containers, this is not the case with order pickers that aren’t always adjustable. These tend to be sized for wooden pallets, which only have a 2” wide center rail. This is a big difference from a plastic bulk bin with a center foot of 4.5” to 11”. Because of this, utilizing an order picker with a collapsible tote can be difficult. Luckily, at

RPP Containers, we have a solution.

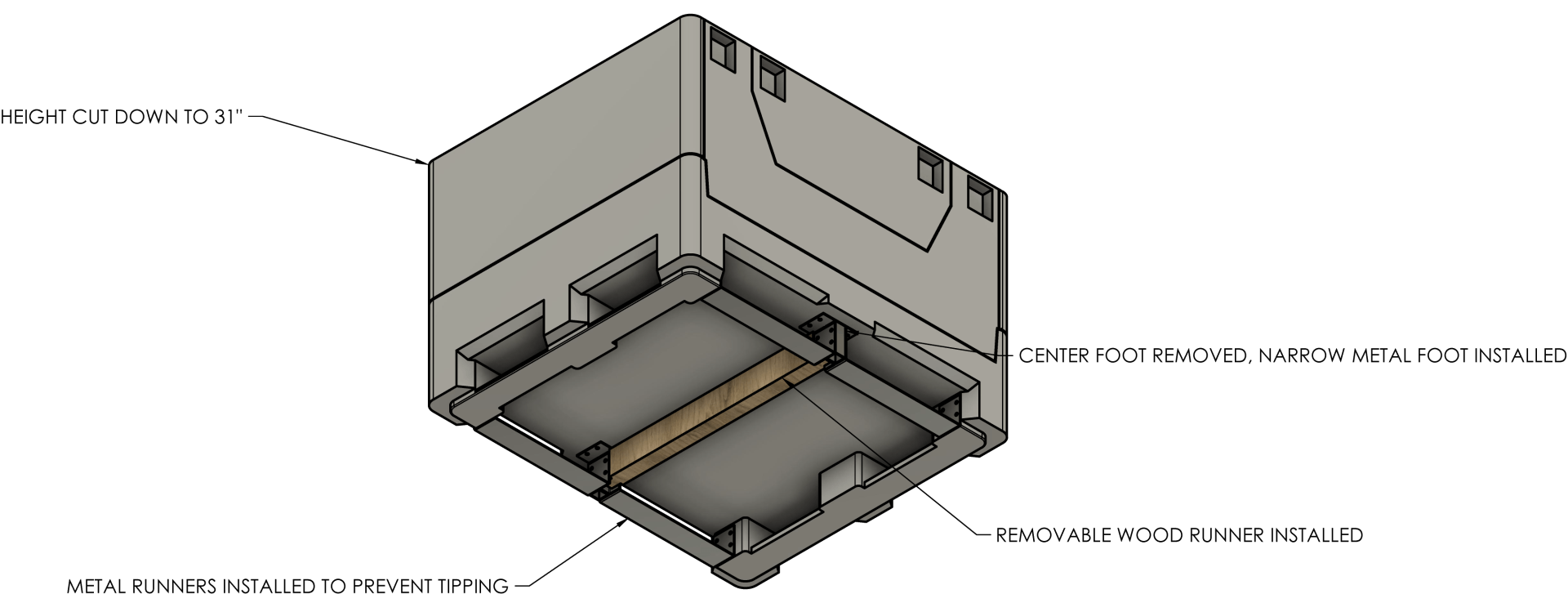

The first step is to remove the existing middle foot. This is cut out with precision to maintain the integrity of the container. There is another pad in the very center of the base that must also be taken off as well as all the fork straps connected to these. Once the area is cleared, special metal brackets are painted to match the container and shaped to hold the new centerpiece. They are then attached to the bottom of the container and remaining outside feet. Once these pieces are in place, a 2” wide plank is inserted and secured with the metal joints.

With these alterations, you don’t have to choose between the benefits of an order picker or those of a plastic bulk container. While this is a major change to the bottom, the bin still retains its weight rating and stackability. It can be accessed properly with an order picker while still offering a bulk tote’s stackability, durability, and protection. Even with this change, it doesn’t lose the option to be moved with a standard forklift. This means that if you employ both order pickers and forklifts, you can still benefit from containers with this modification.

If you have any questions about container customizations, please reach out to us by sending us a message through

Contact@RPPContainers.com

, calling 1-513-489-2244, or by starting a chat on our website, and one of our knowledgeable sales reps will be more than happy to help.

Taylor Turner

|Account Manager

Taylor has been with RPP Containers for eight years as an account manager and has extensive knowledge and experience in the bulk container industry. Taylor works closely with all his customers to find the optimum bulk container for the customer's application.

In the fast-paced worlds of agriculture, manufacturing, food and beverage, seed and feed, and logistics, efficiency isn't just a buzzword; it's a necessity. Handling bulk materials, such as seeds, grains, pellets, resins, and powders, can be a logistical nightmare if you're stuck with outdated or unreliable containers.

In today’s fast-paced agricultural industry, efficiency, food safety, and durability are more important than ever. One of the biggest improvements in produce handling has been the shift from traditional wooden crates to plastic harvest bins. Built with FDA-approved polypropylene and designed for maximum strength.