Inspection Points:

- Feet and corners

- Fork straps

- Hinges/latches

- Sidewalls

- Drop doors

As we’ve detailed in previous pieces, there are many benefits to reusable plastic bulk containers. They can reduce wasted space and shipping costs and increase efficiency and safety. Being durable, they have a long lifetime and free up time devoted to resupplying packaging and allowing you to spend it on more important things. That all being said, sometimes, the cost to switch your entire plant over to reusable plastic containers can be hard to swing. To help ease the burden, RPP Containers has their RefurBest line.

RefurBest containers are previously owned containers that RPP has brought back after they were no longer needed. These could be from rental programs that have been completed or even containers that RPP bought from previous customers. However, they aren’t just your average used containers.

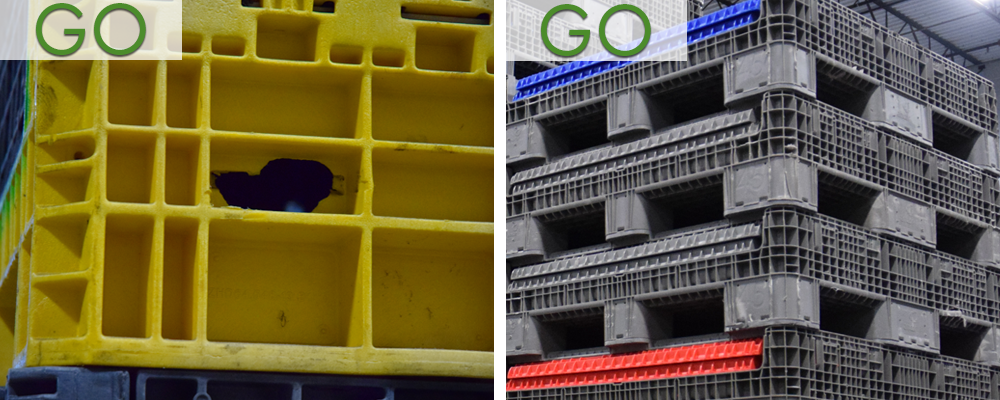

To understand the big difference, you must first learn about RPP Containers’ recycling program. Implementing a large-scale grinder, RPP is able to convert old broken containers into regrinds to be recycled back into new containers for our DuraGreen line. This means that only the best of the best containers are considered for our RefurBest line. If a container is brought in that has a cracked base, broken feet, or holes punched in it, the container can simply be converted into regrind for future containers.

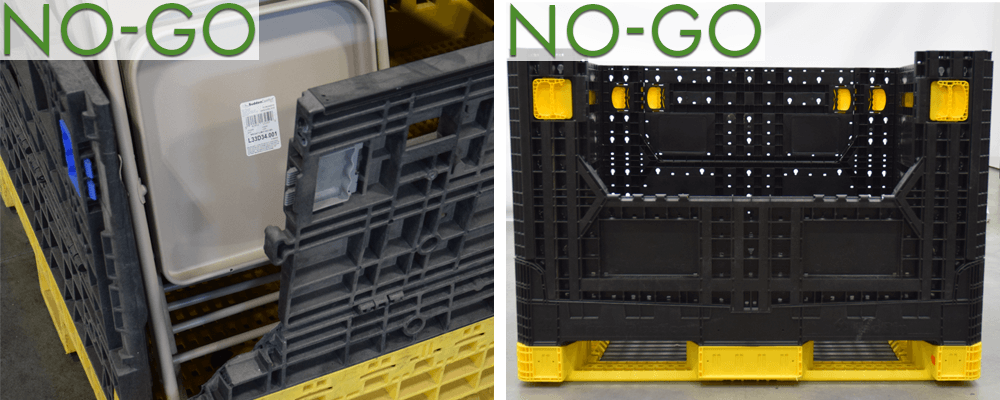

Inspection Point #1: Feet and Corners

Missing or damaged feet are the most critical inspection point and number one reason to remove a bin from circulation. The bulk container's load is carried vertically in the corners down to the ground. Missing or damaged feet interrupts the transfer of weight and is a "NO-GO" condition.

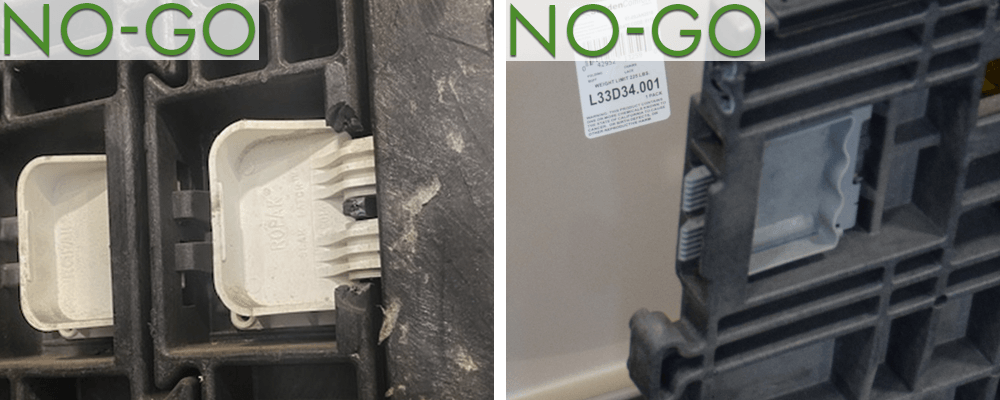

Inspection Point #2: Fork straps

If a bulk container is missing or has a damaged fork strap, it is in a “NO-GO” condition.

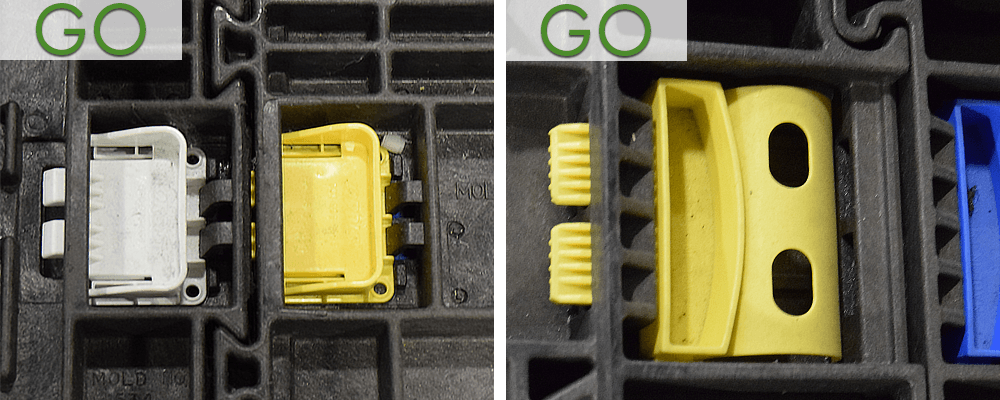

Inspection Point #3: Hinge/latches

Inspect that hinges and latches are present, not damaged, and have a free range of motion. Inspect the condition of the locking tabs. If the latch tabs are broken, then the drop door or sidewall can not safely engage and compromise the bulk container's integrity. Missing and damaged tabs or latches are in "No-Go" condition.

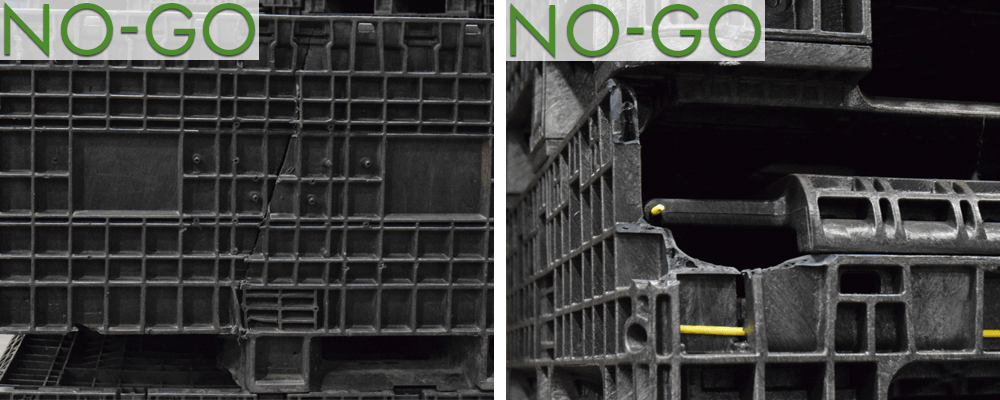

Inspection Point #4: Sidewalls

Bulk containers that have sidewalls with vertical cracking or damage along stacking rail are “NO-GO” conditions. Sidewalls with damaged fingers or hinge rods that prevent proper engagement to the base are also NO-GO conditions.

Inspection Point #5: Drop door

Missing or damaged drop doors prevent the vertical transfer of load to the floor. Bulk containers with missing or damaged drop doors are a “NO-GO” condition.

Our experienced quality assessment team thoroughly inspects each container that comes in. Bins that don’t meet our standards are sent to the grinder for processing, and the others are divided into good and repairable bins. Repairable bins are containers with great structure but might be missing hinges or latches or even have slight damage that doesn’t threaten their integrity. These are sent to our repair team, who will replace the missing parts and do minor welding to repair the containers. Sometimes we can take great walls from an otherwise scrap container to finish a container with an excellent base but ruined walls. This makes it possible to get multi-color bins to help distinguish certain containers.

Inspection Point #1: Feet and Corners

The bulk containers load is carried through the feet and rib structure, down to the ground. 80% or more of the load is carried in the four-corners. Therefore, corners and feet must be damage-free to ensure that weight is transferred vertically down through the corners and fully supported on an even floor or racking surface.

Inspection Point #2: Fork straps

Fork straps are the second critical inspection point for used bulk containers. Missing fork straps create an unsafe condition when handling bins by fork lifts or fork trucks.

Inspection Point #3: Hinge/latches

Latches are a critical part of the bulk container functionality. Latches ensure that the connecting sidewalls are securely engaged and locked into place. Also, that drop doors are positively engaged to the sidewall.

Inspection Point #4: Sidewalls

Cosmetic or minor rib damage to the sidewall of the bulk container is acceptable and contributes to only a minor reduction in bin performance.

Inspection Point #5: Drop door

Bulk containers must have fully functioning drop doors with fully functioning latches and tabs. Bulk container drop doors also require fully functioning hinges or rods that securely attach them to the container wall.

After this process, all the containers, repairable and good, are re-inspected to make sure they meet our standards. Each one is opened to make sure the walls latch properly. The drop doors are inspected for the full range of motion. We collapse them again to make sure they collapse smoothly. The bases are inspected for any cracks that may have been missed or forkstraps that may be close to failure. If they do not pass this second inspection, they are sent to the grinder or back to the repair line.

With the second inspection completed, the containers are meticulously washed with a pressure washer to remove all dirt, grime, and foreign material. Once that is completed, they are all stacked to ensure they fit together safely and securely.

This process makes RPP Containers’ RefurBest line at the top tier in refurbished containers. When you purchase, you can be certain that you will get a fully-functional container at a reduced cost from a new bin. They may have dings, scrapes, and scratches, but they won’t have broken bases, holes in the walls, and missing latches. We are so confident in our process that each RefurBest container comes with a one-year, fully functional warranty. If any of the hinges break or a wall doesn’t latch properly, let us know, and we can get you replacement parts.

If you have questions about our clean and repair program, container buy back and recycling, RefurBest Used Bulk Containers, or any of our other bands or services please contact us by sending us a message or calling 513-489-2244 to speak with an account manager.

Copyright | RPP Containers.