Aerospace Engineering

The Challenge

The customer needed a custom bin to ship extremely high-value wings for drones. No container existed that had dimensions of a width roughly around 32" and a length around 90". The traditional larger bulk containers would not work because they are shipping the drone wings in sets and not large packages with large quantities of wings.

The Solution

The customer requested a strong, durable, and lightweight container and lid. We worked with a local thermoformer to create a completely custom mold for this project.

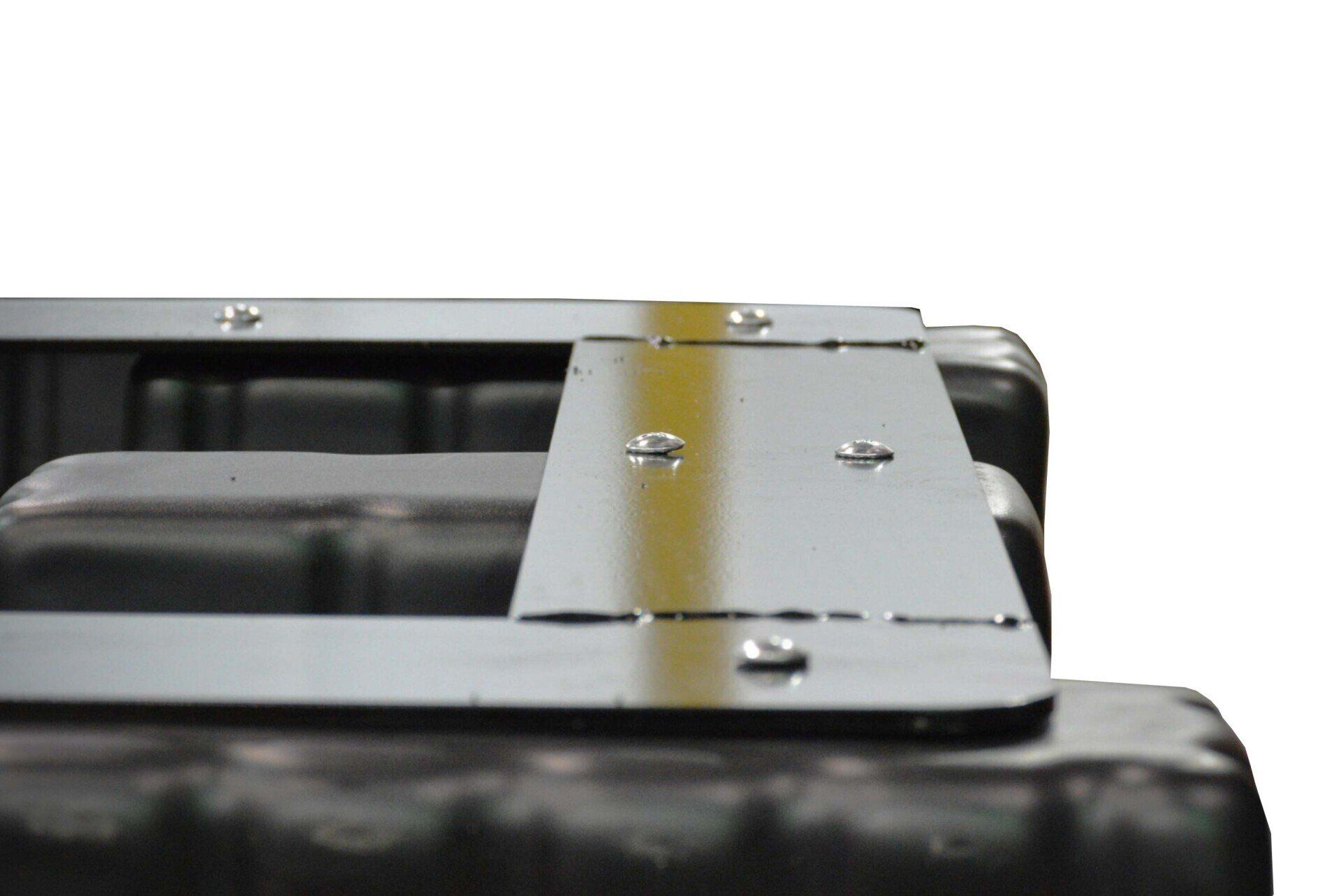

Next, we added steel reinforcements. Steel L-shaped bars were added to the top of the two long walls of the bin. Adding the steel bars to the top of the bin's walls increased the rigidity of the bin.

A plastic divider was added to the center of the bin, running the length of the container. The divider's purpose is to keep the drone wings from shifting during shipment.

The last change we made was to increase the rigidity of the base of the bin by adding metal runners to the length and width of the base of the container. By adding the metal runners to the base, it will strengthen the base. The runners will also keep the container from flexing when a forklift is moving the bin. The metal runners also create fork straps for the container keeping it securely on the forks while being lifted and transported.

The Results

By creating a custom-designed thermoformed bin and lid, we guarantee that the bin is exactly what the customer's applications need. Once the thermoformed bins and lids were created, our CustomBulk® technicians went to work adding L-shaped steel bars to the top of the bin's walls. Metal runners were also added to the base of each bin to give additional strength to the bins and creating fork straps. We were able to create a completely custom bin to meet the customer's very specific applications needs. The customer is now able to safely and securely ship and store their custom-length delicate drone wings.