The case for foldable IBC containers – Resins, Powders, Pelletized Products and other Flowable Materials

January 18, 2021

The case for foldable IBC containers – Resins, Powders, Pelletized Products and other Flowable Materials

Manufacturing, storing, and shipping non-liquid “flowable” materials presents a special set of obstacles that aren’t present in other industrial applications. When storing materials such as

resins

,

powders

,

pelletized

products, or the like, the material inside your container can put an immense amount of lateral pressure on the walls. This lateral pressure can create a host of problems for safe storage, stacking, and transport, but these are issues that can be resolved by using RPP Container’s line of foldable IBC containers, or as we call them, our

Reusable Plastic Gaylords

.

The Old Way

Historically companies have opted for 1 of 2 main options for handling these types of materials. They would either use a corrugated cardboard gaylord on a wooden pallet or a nylon Super Sack on a wooden pallet. While these two options technically do hold the material, that is where their redeeming qualities end. Over time, the lateral pressure of flowable materials causes the walls of both of these options to bow significantly. This makes stacking unstable, which is why the majority of Super Sacks and cardboard Gaylords can only be safely stacked two high when loaded. Both of these options are prone to punctures and cuts, which can cause major cleanup issues and loss of product and money when material is able to leak out. Lastly, these containers can normally only be used a couple of times before they must be disposed of and replaced, which just adds to our already overflowing landfills.

The new and improved way

RPP Containers’ collapsible Reusable Plastic Gaylords

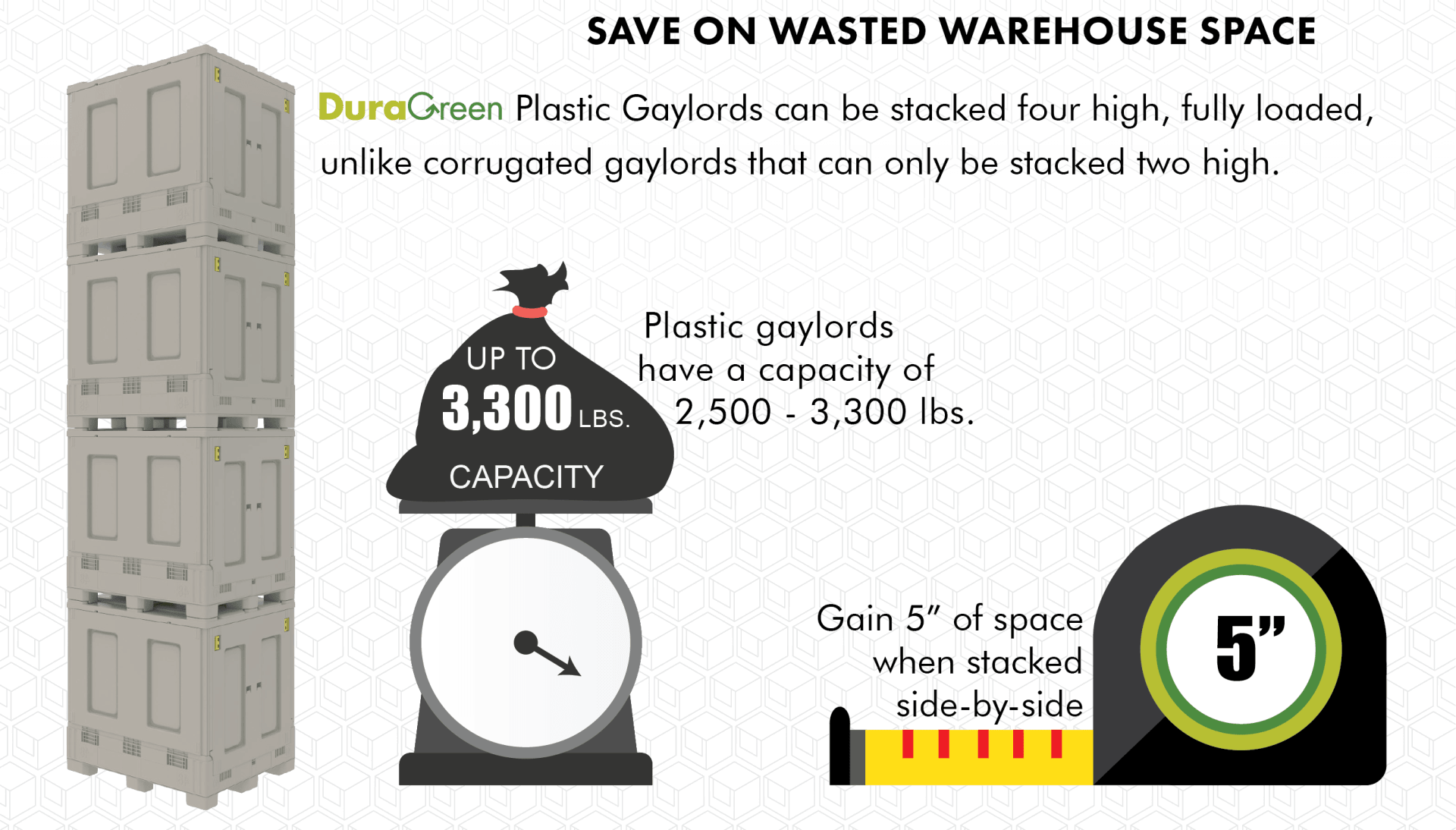

improve storage efficiency, safety and help reduce your company’s environmental impact as well. Depending on the weight and density of your material RPP Containers offers a standard Reusable Plastic Gaylord

, along with heavier duty options with fiberglass or steel reinforcement

, meaning you can safely store up to 3300 lbs. of material per unit.

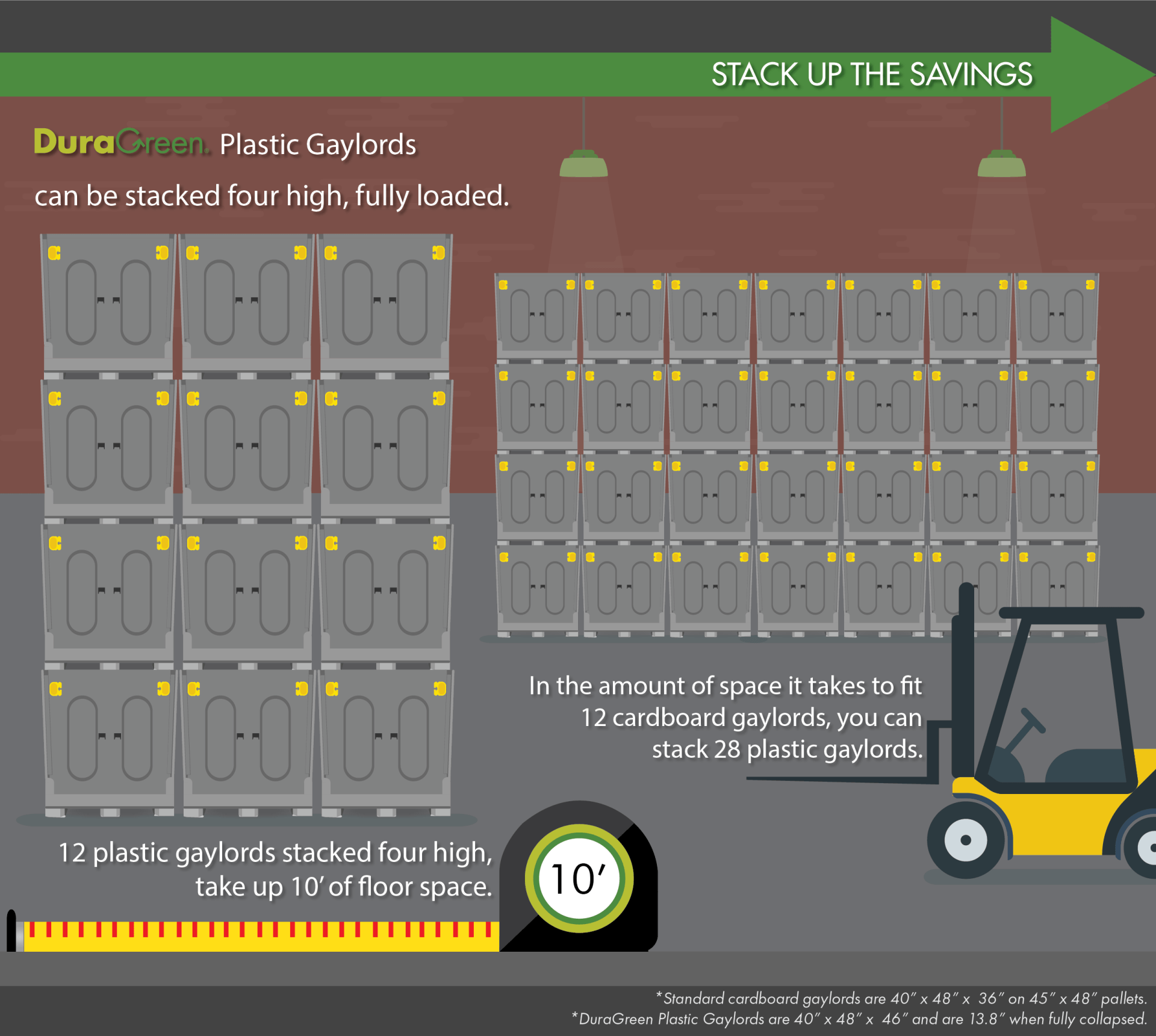

With our foldable IBC bins , you do not have to worry about bulging walls or insecure stacking. These containers can safely stack four units high, in neat, uniform rows, helping to free up a significant amount of floor space that would have been wasted by less efficient containers. The molded in pallet bases on our Reusable Plastic Gaylords line nest into one another to create a secure, centered, and reliable stack of material. Their injection molded walls also help to protect from impacts or punctures, so you can be confident that your material is contained in the bin where it is supposed to be, rather than spilling out on the warehouse floor.

With our foldable IBC bins , you do not have to worry about bulging walls or insecure stacking. These containers can safely stack four units high, in neat, uniform rows, helping to free up a significant amount of floor space that would have been wasted by less efficient containers. The molded in pallet bases on our Reusable Plastic Gaylords line nest into one another to create a secure, centered, and reliable stack of material. Their injection molded walls also help to protect from impacts or punctures, so you can be confident that your material is contained in the bin where it is supposed to be, rather than spilling out on the warehouse floor.

Quick payback on your investment

Whichever way you look at it, our foldable IBC bins

allow you to quickly recoup your upfront investment in the bins. By using less than half the floorspace of the alternative you can reduce square foot storage costs for your material and dedicate the saved space in your plant to other value add processes. With their superior protection of your product from impact, spillage, or stacks tipping over you will have less waste and loss of your particular product. The long lifespan of these bulk containers means one purchase of the bin will outlast tens or hundreds of purchases of expendable packaging. Lastly, when these containers do finally reach the end of their usable lifespan, the plastic can be

recycled

, and the value of the material can be used towards the purchase of replacements.

If you have any questions on our Reusable Plastic Gaylords

or any of our other bulk container products please do not hesitate to reach out to us here at RPP Containers and one of our knowledgeable sales associates will be more than happy to help.

Article by: Tyler Brady | Account Manager Email Tyler Call Tyler 513-208-2238

Article by: Tyler Brady | Account Manager Email Tyler Call Tyler 513-208-2238

In the fast-paced worlds of agriculture, manufacturing, food and beverage, seed and feed, and logistics, efficiency isn't just a buzzword; it's a necessity. Handling bulk materials, such as seeds, grains, pellets, resins, and powders, can be a logistical nightmare if you're stuck with outdated or unreliable containers.

In today’s fast-paced agricultural industry, efficiency, food safety, and durability are more important than ever. One of the biggest improvements in produce handling has been the shift from traditional wooden crates to plastic harvest bins. Built with FDA-approved polypropylene and designed for maximum strength.