Distribution center for groceries & house hold items

The Challenge

The customer needed to create a way to transport cardboard sheets for packaging to multiple stations throughout the warehouse. Once the packaging is ready it needs to transported to multiple stations throughout the warehouse. The customer had no way to transport the cardboard throughout the warehouse efficiently, and due to the warehouse's layout, forklifts were not an option.

The Solution

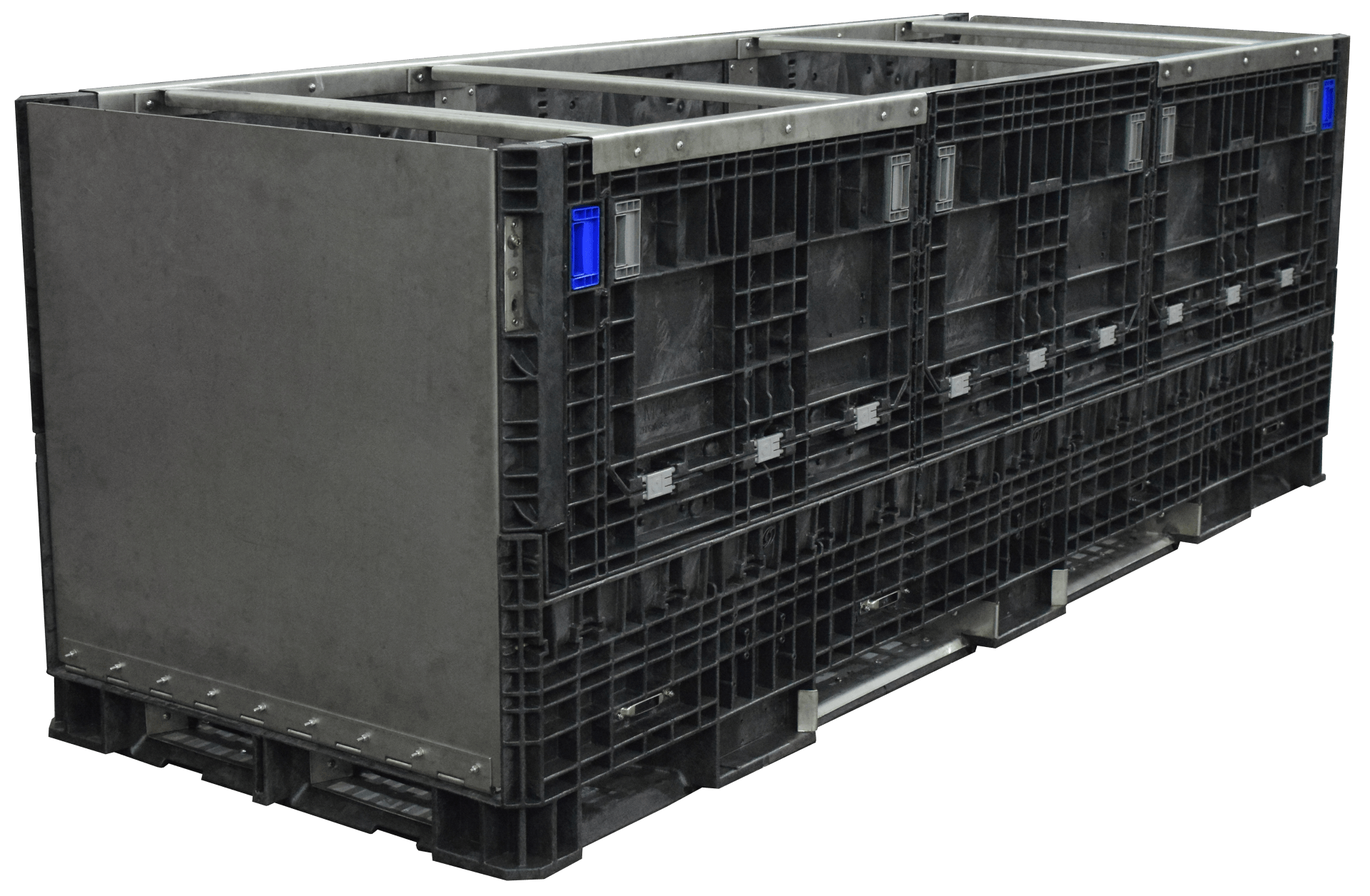

We started with creating a solution for moving the cardboard sheets safely and efficiently throughout the facility that would work with the facility's layout. The solution we created is a de-palletized container that attaches to a custom dolly. There is an articulating arm on the front of the dolly that can be joined to another dolly with a hitch so that multiple dollies can be joined together and transports throughout the facility.

Next, we needed to take care of creating access points at both ends of the container. A stainless steel wall that doubles as a ramp were added to both ends of the container. The ramps have to be easily lowered so that the underwater robotic equipment can be safely rolled into the container and out of the container without causing any damage.

Steel reinforcement bars were added to the top of the container to keep the container from collapsing. The bars also give additional strength to the container since the two end walls have been removed to add stainless steel ramps.

To increase the protection of the container's contents, a reinforced lid was added. With the container being stored on the deck of a ship, the lid needed to be tightly secured to the container. Four heavy-duty straps were added to keep the lid securely attached, no matter the boat's movement or the amount of wind.

Inside the container, two rails run the length of the container. The purpose of the two rails is to hold the underwater robotic equipment securely in place, during transit, or while on the ever-moving deck of a ship.

The Results

With this container, the customer could be sure that their product was safe, secure and would keep it from moving while in transport and on the deck of ships. The container has two ramps one on each short end of the container so that the underwater equipment can be easily and safely rolled into or out of the container without causing damage. Inside the container there are two rails that run the length of the container. The purpose of the two rails is to old the underwater robotic equipment securely in place, during transit or while on the ever moving deck of a ship.

Contact Us

We will get back to you as soon as possible.

Please try again later.

Info Links

Other Brands

Copyright | RPP Containers.