Custom Screen Printed Sign Container

The Challenge: How to protect and ship large quantities of screen printed signs?

The customer needed a container to stack 250-1000 signs at a time to store and ship. The signs are 13" x16.5" and 12.5" x16," and they are currently only able to stack 300-500 at a time. The customer is currently using make-shift aluminum walls secured with shrink wrap to contain the product before packing. The walls of the make-shift aluminum are very unstable, and the ink gets scraped off of the sign easily, making it incredibly difficult to load/unload quality products.

The Solution:

The customer would like to stack more pieces, but the structural integrity of the current stacking solution limits them on height. They also need containers that can be moved around more easily, as their current process is very limited.

Option One:

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

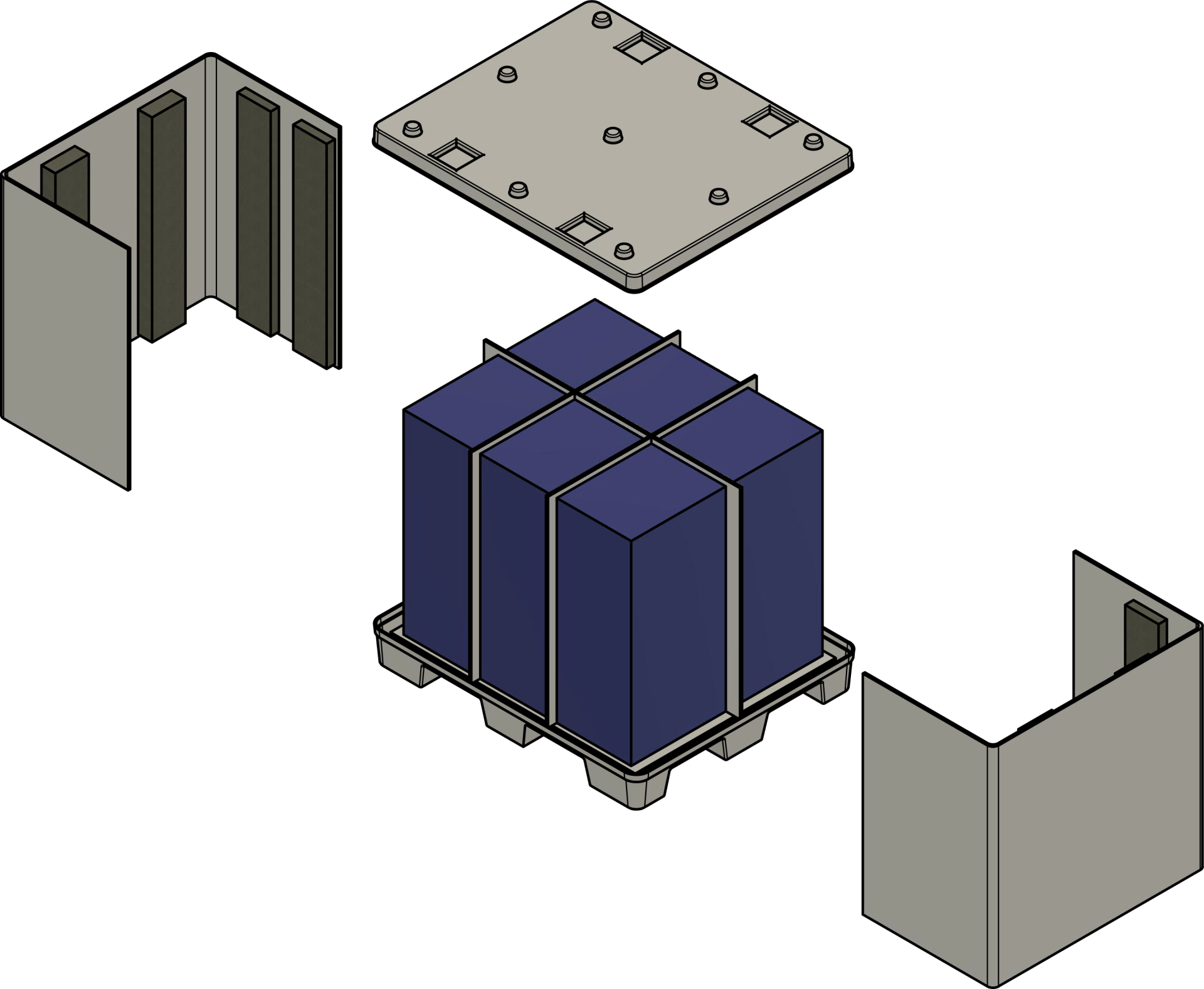

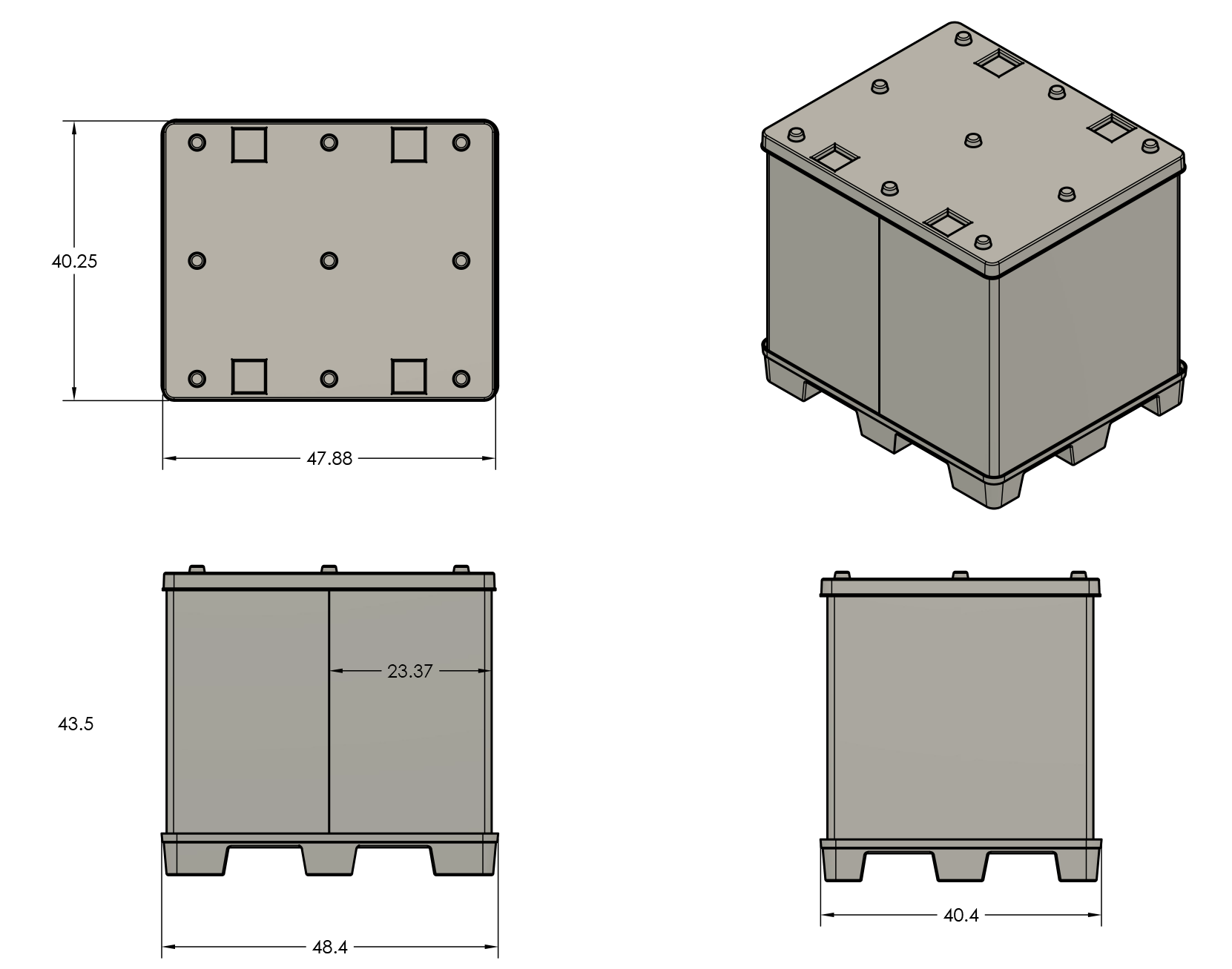

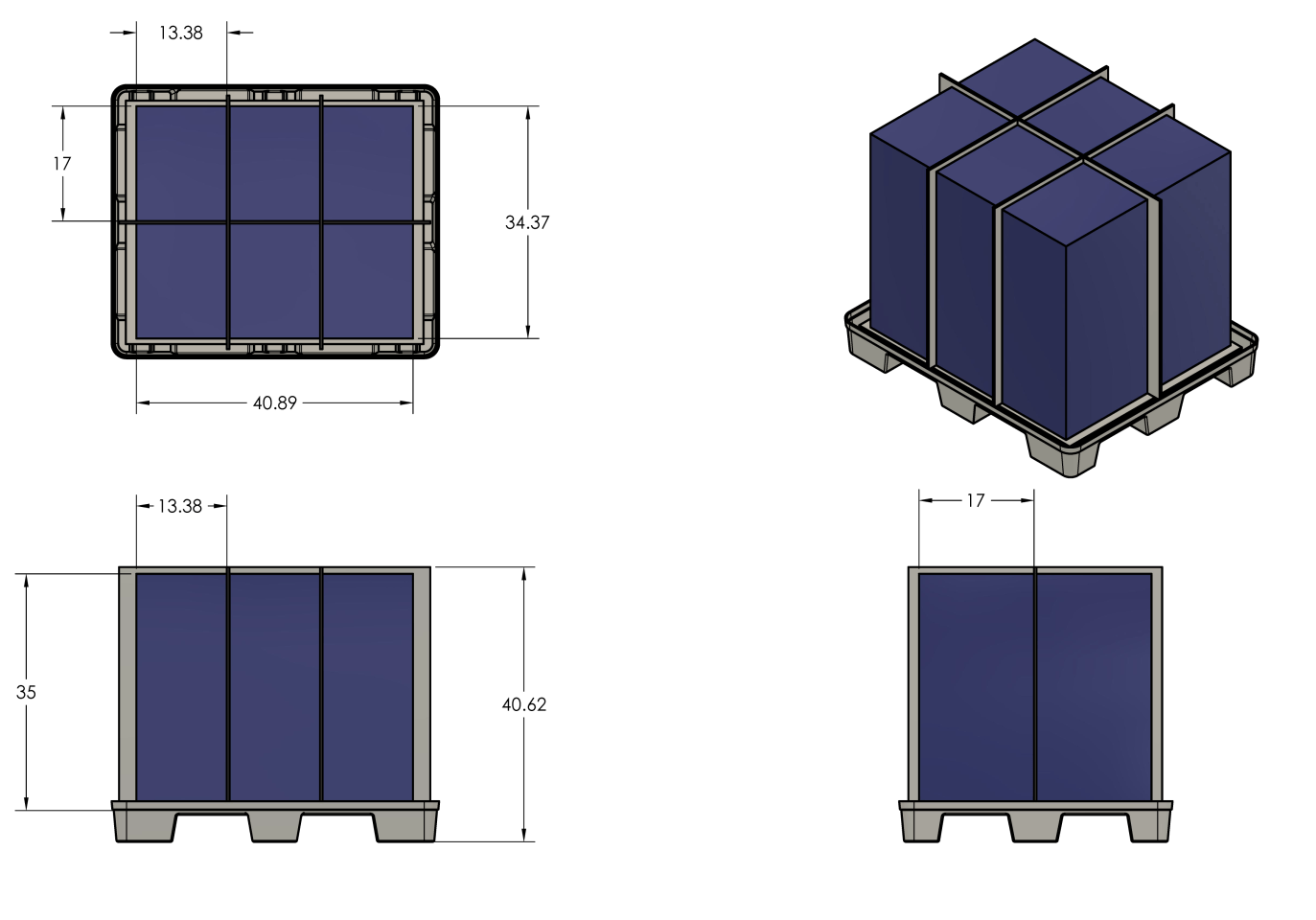

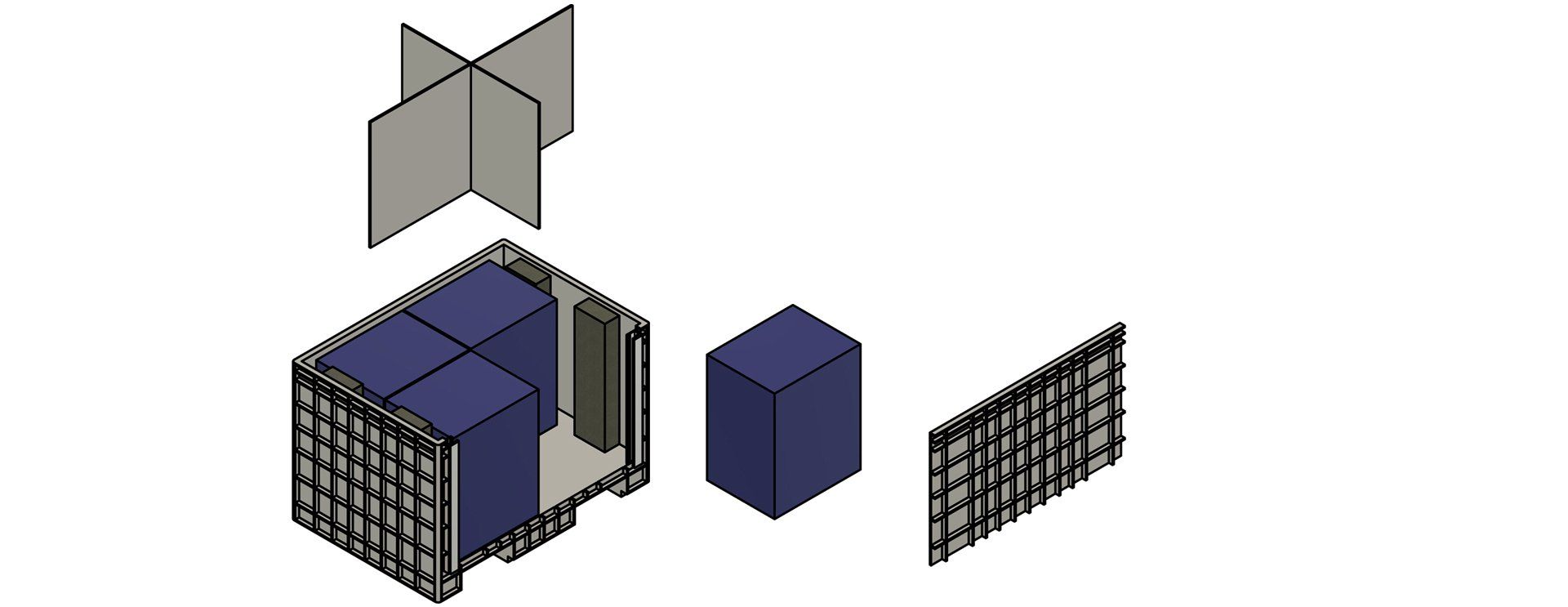

The first option, DGC402845-SL-D, uses a collapsible corrugated cardboard pallet pack measuring 40" x 48" x 45". With this option, there would be a "split sleeve" for easy loading and unloading of the signs. The customer would be able to fit six stacks inside with a divider to help stabilize and compartmentalize the signs.

Option Two:

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

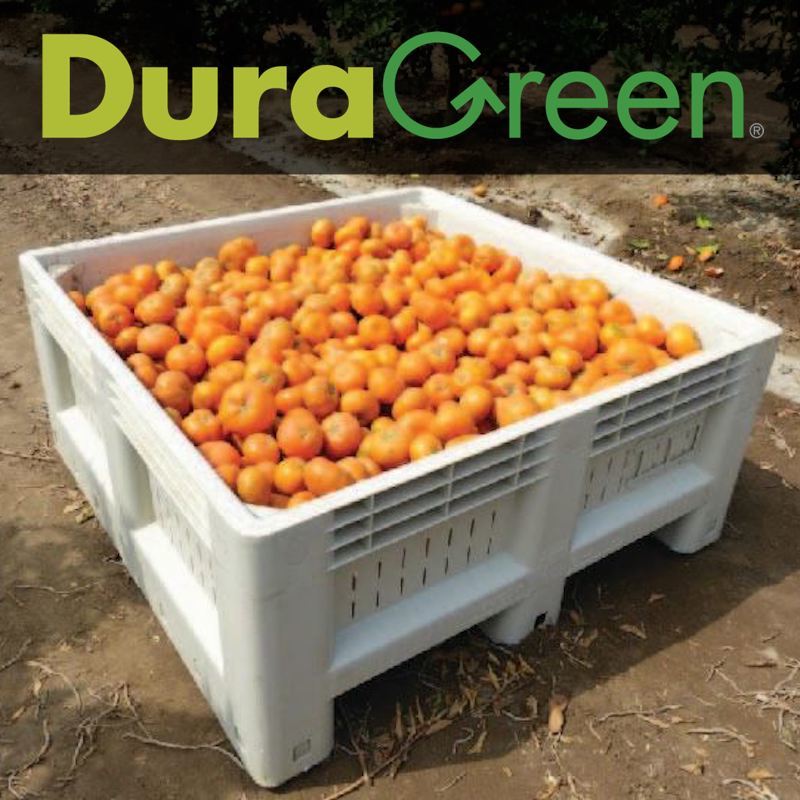

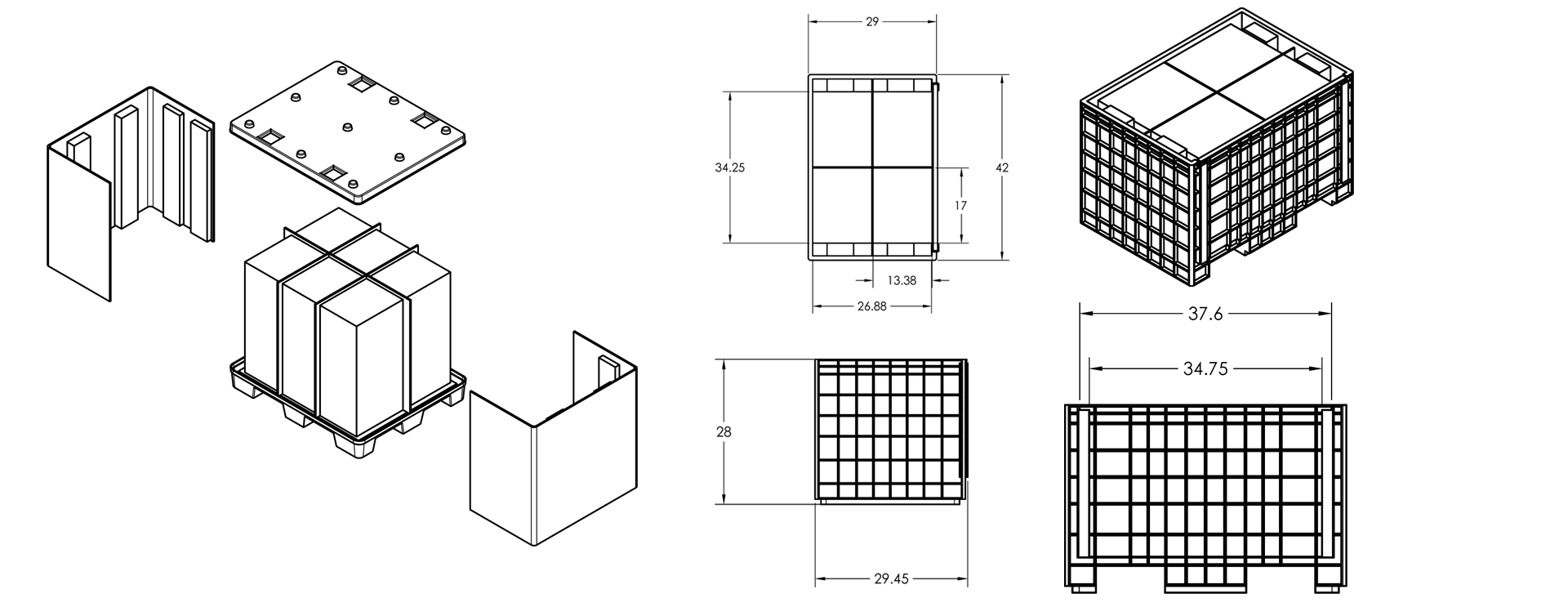

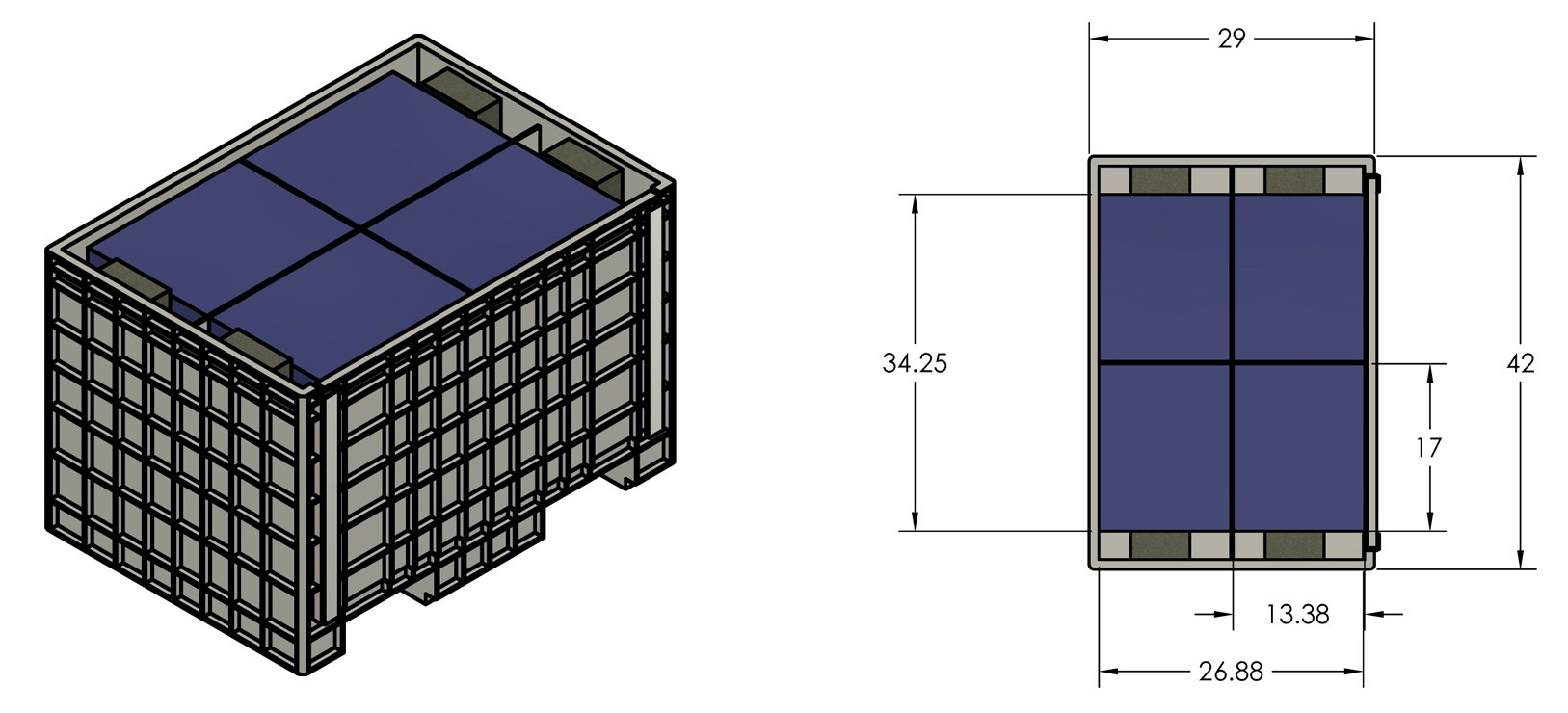

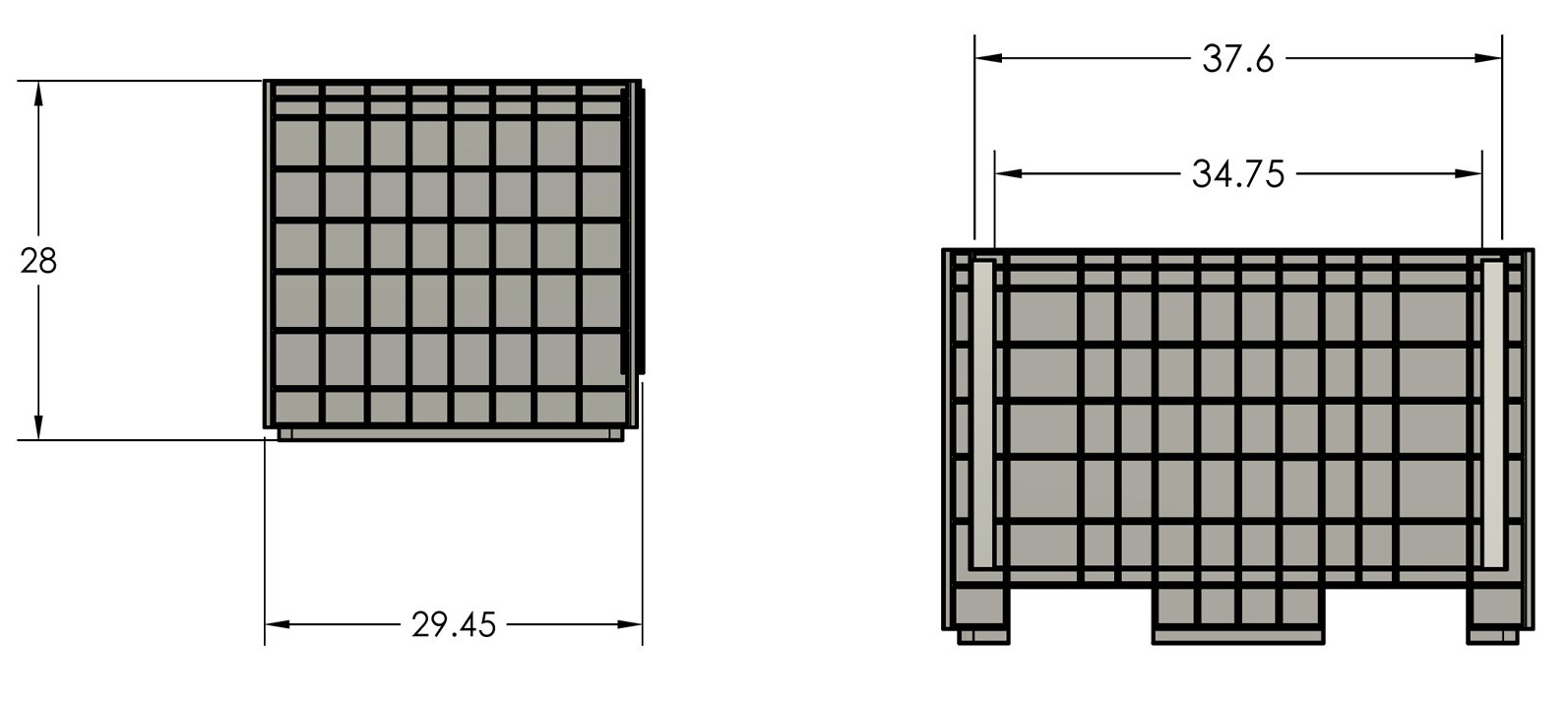

The second option, DGC422829-RW1-D, uses a non-collapsible solid wall container measuring 42" x29" x28". This option includes a removable sidewall on one of the 42" sides allows full access to load and unload the signs securely. The customer would be able to fit four stacks of signs inside with a custom divider to compartmentalize the signs.

The Results:

The customer will benefit from having a more stable container with specific dividers compartmentalizing the different stacks of signs. They will also be able to easily load and unload products with minimal damage to the signs. The container will ensure they are able to fit more stacks than with the make-shift structure they were using before. By making these simple modifications, the customer will have more stability with transporting the signs, as well as less damage to products during the load/unload process. We were able to create a completely custom bin to meet the customer's needs.

If you have an application that needs a custom solution, visit our CustomBulk section of the website to see examples of our custom solutions and learn about our custom capabilities.

Info Links

Other Brands

Copyright | RPP Containers.