Improve Efficiencies and Storage Costs with Collapsible Bulk Containers

Leveraging return ratios to improve shipping efficiencies and cut down on storage costs.

RPP Containers offers a variety of lines of collapsible bulk containers and nestable bulk bins to help your company save on closed-loop shipping programs. Closed-loop shipping is becoming more popular for intra-company shipping along with ongoing parts shipments from component manufacturers to other industrial companies.

Expendable packaging and the “old way” of doing things.

Take an automobile manufacturer as an example. They partner with a variety of parts manufacturers to make their final product. They may receive driveshafts from one company, seating materials from another company, windshield wipers from another etc. All of these materials are shipped into the main manufacturing plant for final assembly to make the full, finished car. Historically these smaller part suppliers would ship their respective items in expendable packaging, be it cardboard boxes, wooden crates, or items shrink wrapped onto wooden pallets. This meant that after the items were unpacked, now there is a mountain of used packaging that takes up floor space and needs to be discarded. Storage and disposal costs of these single use expendable packaging products lead to increased cost and were terrible for the environment.

Collapsible bulk containers and return ratios

Using expendable packaging in the example above creates unnecessary costs and also has a negative environmental impact, so in these and many other instances the transition to reusable bulk containers is a no-brainer.

Using the same example above, many automotive manufacturers have standardized on a particular collapsible bulk container size that all of their suppliers use. So, the company making components for the driveshafts would send their parts to the automotive manufacturer in a bin similar to our DuraGreen DGB454534-2. When that container was unloaded, that 34” tall bin is then simply collapsed down to just 12” tall and set aside. As more bins are unloaded, the empty bins stack neatly together, and once enough have been set aside, the empty bins get shipped back to the driveshaft component manufacturer to be filled back up with more parts.

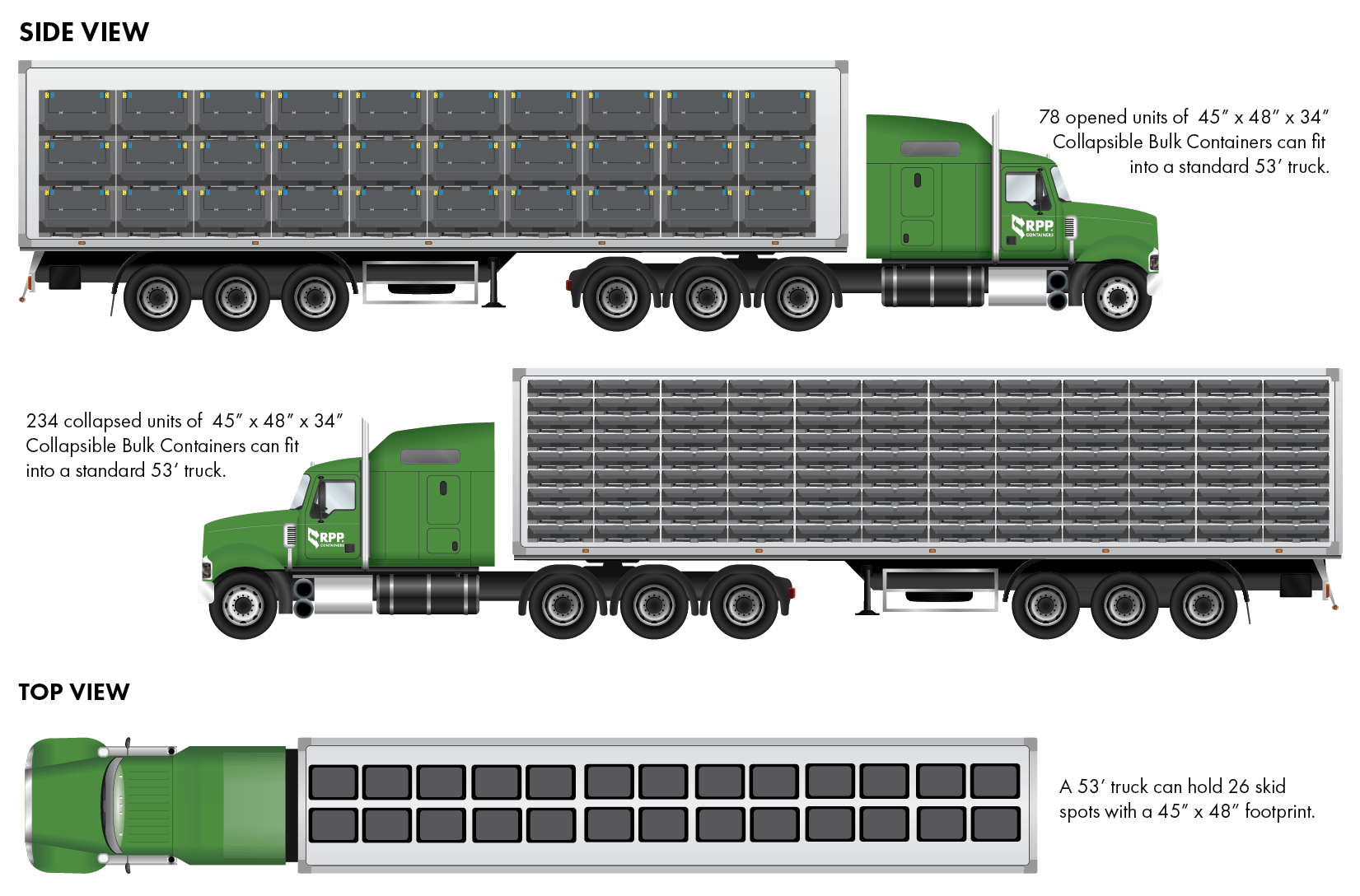

This is where the beauty of return ratios really makes its mark. In this specific size example of a 45x48x34, you can fit 78 units into a standard 53’ truck. When the bins are being returned empty, you can fit up to 234 units into the same size truck, giving the bin a return ratio of 3 to 1. These return efficiencies greatly reduce return freight costs and help speed up the bin payoff time. This same 3 to 1 ratio means that when the packaging is being set aside it takes up significantly less space than discarded cardboard, plastic wrap, and pallets.

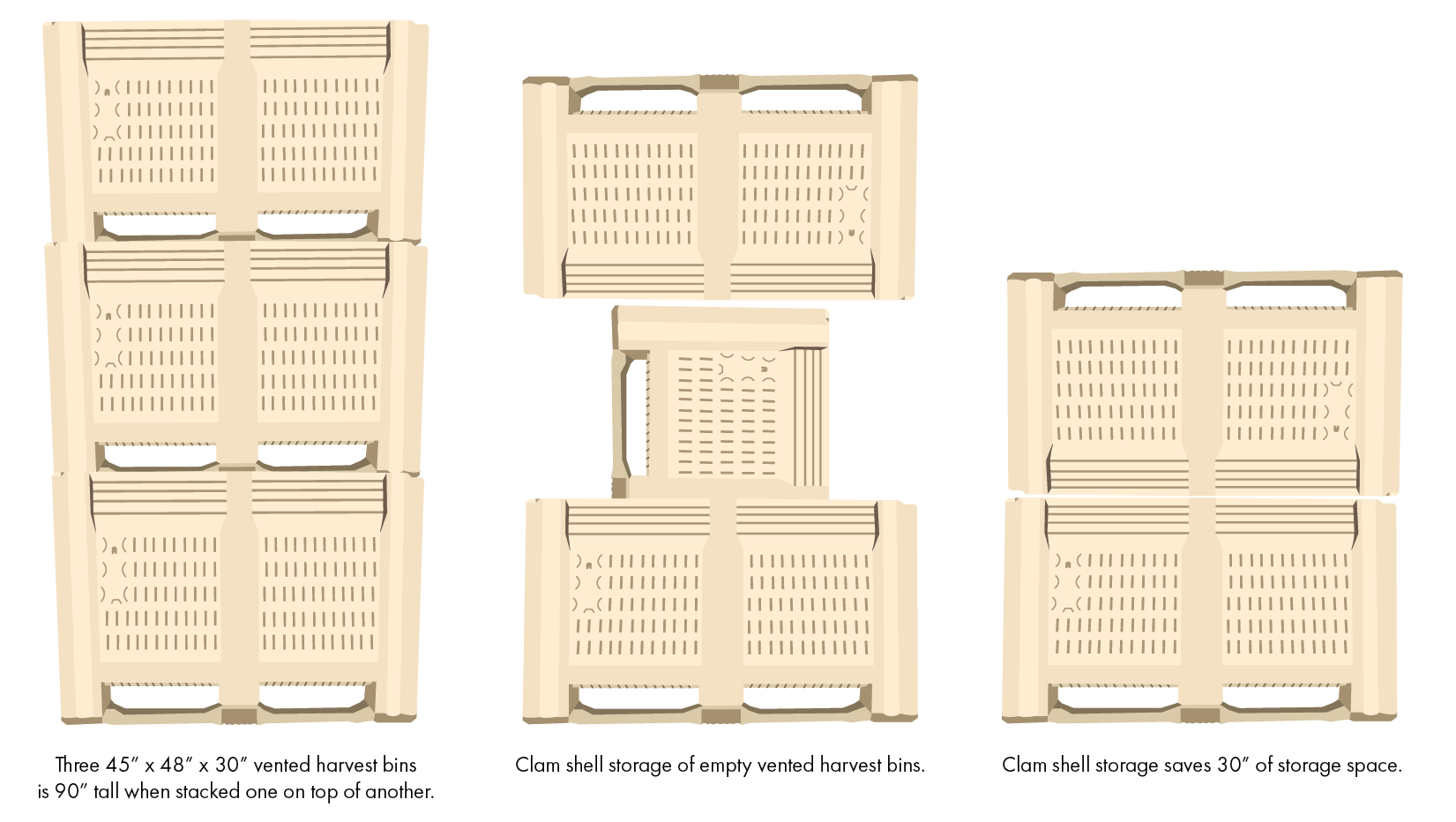

RPP Container’s wide selection of reusable bulk containers offer return ratios that go as high as almost 7 to 1 with our pallet pack containers. Even our non-collapsible bulk bins are engineered in such a way that they can be clam shelled together to help save space on return shipping and empty container storage.

If you have any questions on how to optimize your shipping and storage programs with reusable packaging please do not hesitate to reach out to us and one of our skilled salespeople will be more than happy to help.

Info Links

Other Brands

Copyright | RPP Containers.