Modular bulk containers and dunnage bases

Modular bulk containers and dunnage bases

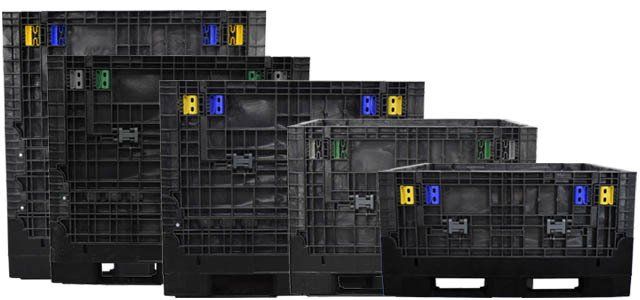

RPP Containers offers a wide range of premium collapsible bulk containers in many different footprints and heights. The vast majority of these sizes were designed over the years to efficiently fill up a truck, or to fit the most common needs of the industrial supply chain. RPP Containers prides itself on offering solutions for a wide range of industries and different applications which is why our line of modular height and dunnage base collapsible bulk containers is so useful.

Height flexibility with extension collars

Our most common collapsible bulk container offerings are in the 45” x 48” footprint, but with our extension collar sets, we can mix and match containers and collars to come up with a variety of additional heights to fit your needs. We have height options including to 25”, 34”, 42” and 50”, with the addition of our 7” and 10” extension collar sets we can mix and match containers and collars to come up with a variety of additional heights. These collars can also be stacked upon one another to create extended height bins in excess of 50” tall. Having the option of custom sized containers, customers have shipped a variety of large objects and have used the containers for multiple applications. With a base of 45” x 48” x 25” and 45” x 48” x 34” the options for semi-trailers are almost limitless.

Dunnage base containers

Beyond simply needing a tall container to ship awkwardly shaped or overly tall items, our extension collars are also common and extremely useful for customers who use dunnage or protective layer pads to separate their items while in shipment. Many cell dividers or other dunnage partitions are made to collapse when not in use and the partitions are usually then palletized onto a wooden pallet and then set off to the side or sent back with empty containers. Palletizing these parts separately leaves them more prone to damage during shipment as well as more likely to be misplaced or lost between freight terminals.

By adding on a 7” collar or 10” collar to a standard collapsible container, you gain a compartment in the bottom of the bin that can be used, even when the bin is collapsed. This means that the collapsed dunnage or partitions can be stored inside the collapsible bulk container for storage or return shipment.

Aside from needing a tall container to ship different sized items, our extension collars are also extremely useful for customers who use dunnage or protective layer pads to separate their items while in shipment. Our collar extensions allow for standard collapsible containers to have a compartment at the bottom of the bin that can be used, even when the bin is collapsed. This means that the collapsed dunnage or partitions can be stored inside of the collapsible container for storage or the return shipment. This is useful because many other cell dividers or other dunnage partitions are made to collapse when not in use and then partitions are often palletized onto a wooden pallet and set to the side, or sent back with empty containers. This gives significantly improved protection during shipment and makes it easier to maintain each divider set with the bin it is designed for, regardless of how much the bin needs to be moved or shipped around. After product has been removed from the bin, the dunnage can simply be collapsed inside the container for safe keeping until it is needed again.

Custom solutions for your needs

With our ability to cut and weld containers, along with the above capabilities of our modular height bins, RPP Containers is able to help come up with the right packaging to ship and protect your products. If you see something that is close, but not quite what you need, RPP Container’s knowledgeable sales staff and dedicated custom team can help you find the right product or solution to your particular application.

Info Links

Other Brands

Copyright | RPP Containers.