Shock-Absorbent Containers

The Problem: How to protect and ship a highly calibrated machine without causing misalignment?

We recently had a customer that needed to ship delicate items overseas. The product was a highly calibrated machine, but the roughness of the road and jostling on the ocean was causing the calibration to become off. This was an expensive product, and it was suffering misalignment during transportation before even reaching the customer. It needed to be protected from not only sliding but also the vibration of transportation. We were able to come up with a solution to secure the machine tightly to the base of the container and made the base itself able to absorb the shock of the road.

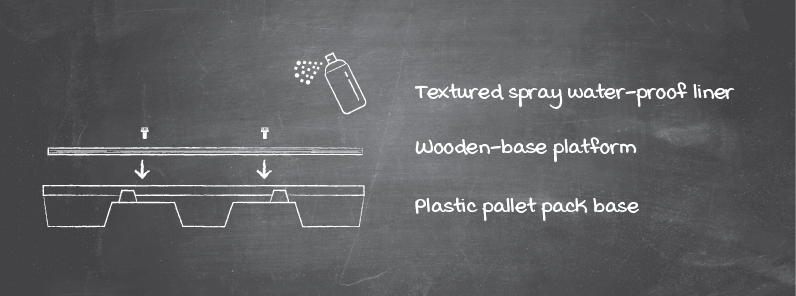

Step One:

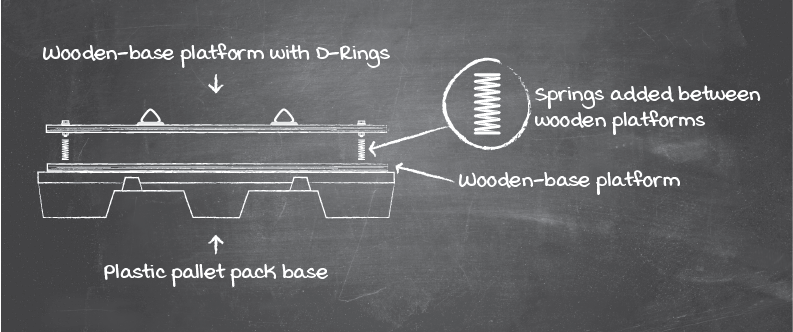

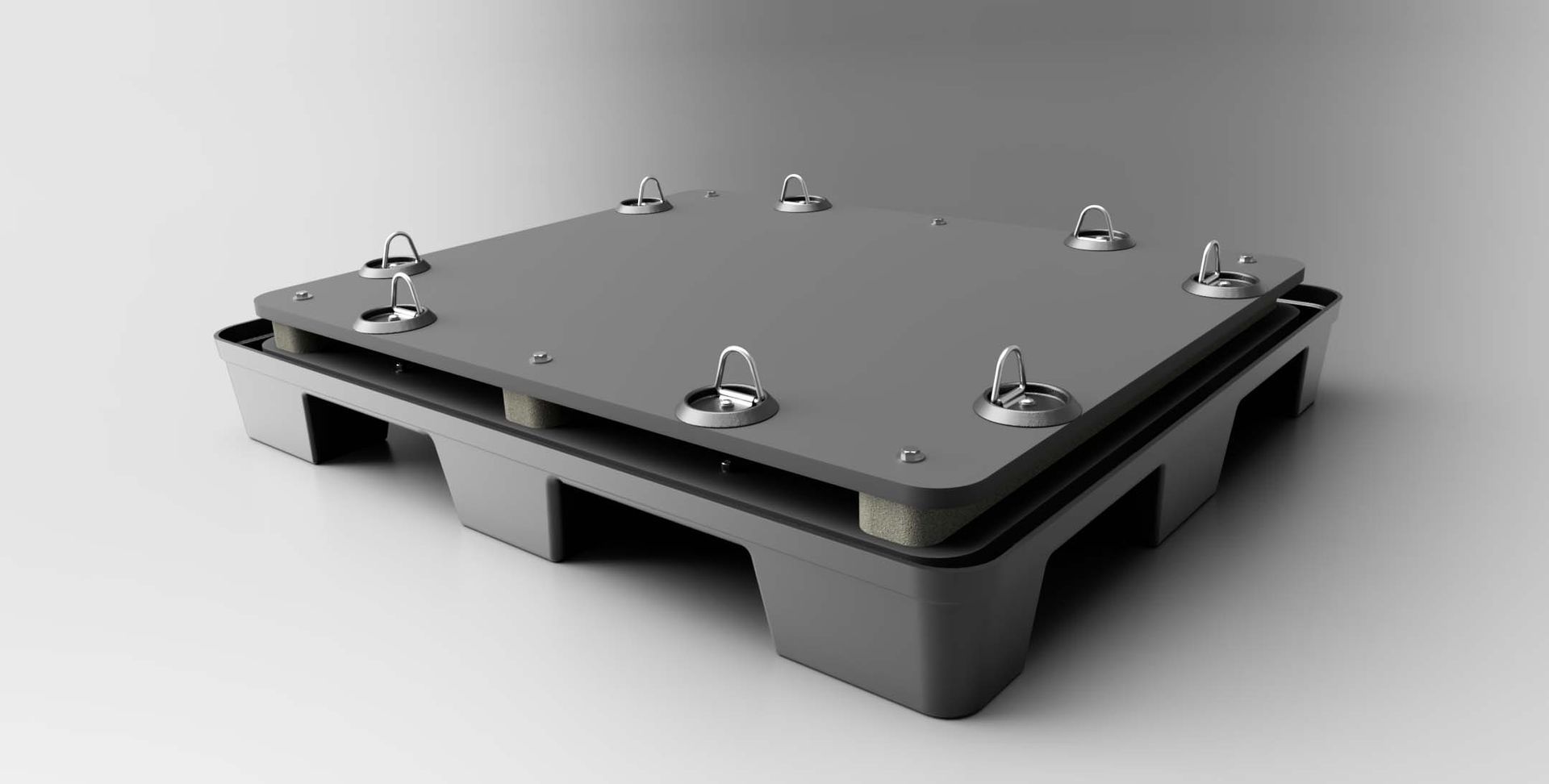

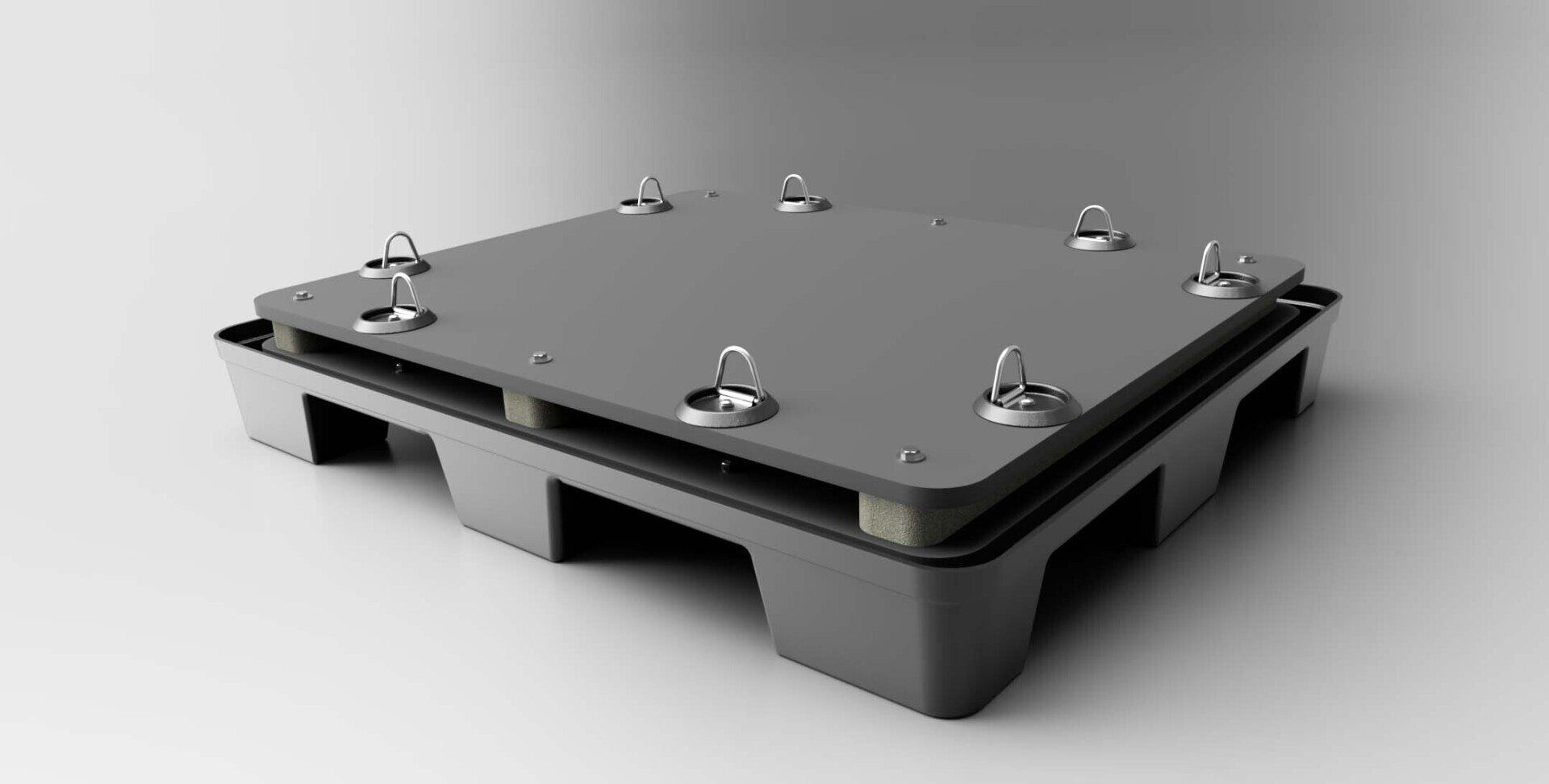

We started with a wood-based platform that would be mounted to the pallet pack base. This provided decent strength at a lower cost to the customer. To protect the wood from rot, we added a water-proof liner to the boards. The liner also added texture to help add some grip to prevent the merchandise from sliding. With a base to start with, we could move on to securing the customer’s product.

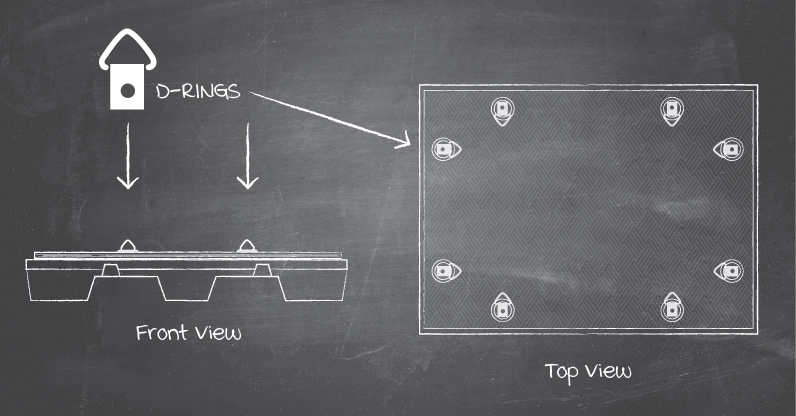

Step Two:

Next, we needed to take care of securing the machine to the wooden platform on the container. If the product was left loose, it wouldn’t matter how good a shock absorber the floor was. A big enough bump in the road could still send the merchandise bouncing or sliding, undoing the calibration. To prevent this, we installed multiple D-Rings along the floor in specific locations so the customer could tightly secure the machine in place.

Step Three:

The last change we made to increase protection was to make the base itself a shock-absorbent platform. This would help cut out all the vibrations from the drive to the product’s final destination, saving the company from product damage during transportation. By taking another board to the platform and installing strong springs in the corners, we could assure a strong base with a good amount of absorption. The springs were designed to be adjustable to handle the weight of the customer’s product while handling vibrations from shipping. For added protection, we sandwiched a layer of permeable foam between the panels.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

With these modifications, the customer could be sure that their merchandise was safe, secure and would maintain the calibration along its route. The D-rings and textured liner allowed them to tightly secure their machine to the base of the container to prevent any sliding. The springs and foam helped to protect against the shock that was ruining the alignment of the merchandise.

Info Links

Other Brands

Copyright | RPP Containers.